The Department of Science and Innovation (DSI) drives South Africa's circular economy with innovative emissions abatement technology

As the reality of climate change bears down on us all, enabling a global transition towards a more circular economic model has become an absolute priority. South Africa, with its considerable economic reliance on carbon-intensive industries like coal-fired power generation, faces some large, unavoidable challenges when it comes to the country’s impact on the climate crisis.

However, the nation is emerging at the forefront of powerful renewable energy solutions - harnessing cutting-edge innovations such as Multi-Pollutant Emissions Abatement Technology to convert harmful emissions and waste streams into valuable industrial resources.

By facilitating the adoption of new technologies, the Department of Science and Innovation (DSI), and all partners involved, are paving the way for South African industries to reduce their environmental footprint while opening up new economic opportunities across sectors like energy, manufacturing, agriculture and beyond.

Africa's emissions impact and the need for circular solutions

While Africa accounts for just 4% of global carbon emissions, the effects of climate change disproportionately impact the continent. In 2021, global carbon dioxide (CO₂) emissions reached 37.12 billion tonnes, with the top emitters being China (11.47 billion tonnes), United States (5 billion tonnes), India (2.7 billion tonnes), Russia (1.75 billion tonnes) and Japan (1.07 billion tonnes). Africa's 1.45 billion tonnes seem rather smaller in comparison, given the size of the continent, according to the Global Carbon budget 2022.

However, within Africa, South Africa stands out as a major polluter at 435.9 million tonnes, accounting for just over 30% of the continent's total emissions alone. The country's heavy reliance on coal power generates nearly 85% of its carbon dioxide (CO₂) output, as discussed at the 2023 African Climate Summit in Nairobi, Kenya. With statistics like these, it is evident that South Africa is a prime candidate for adopting circular economy solutions to reduce emissions and environmental impact.

The Department of Science and Innovation (DSI) is at the forefront of this drive, partnering with local and international experts to develop cutting-edge multi-pollutant abatement technology. This innovative solution aims to capture harmful flue gases and carbon emissions, converting them into useful industrial products and low emission energy sources.

Source: Aljazeera

CoalCO2-X™ - Repurposing harmful emissions into fuels and fertilisers

A prime example of innovation is the CoalCO2-X™ programme, funded by the Department of Science and Innovation (DSI). The goal? Curbing emissions from South Africa's hard-to-abate sectors, such as the country’s coal-fired power plants, by capturing flue gases like carbon dioxide (CO₂), nitrogen oxides (NOₓ) and sulphur oxides (SOₓ).

Through advanced conversion processes, these captured gases can be transformed into valuable products like diesel and fertilisers. Green ammonia synthesis, currently being demonstrated by Fraunhofer IGB in Straubing, supported by Germany’s Federal Ministery of Education and Research (BMBF), will play a crucial role in the project. The captured flue gases will be utilised as raw materials and then synthesised with ammonia and hydrogen, and eventually green ammonia and green hydrogen - all of which are key to enabling the decarbonisation of South Africa’s agrochemical and energy sectors.

Subsequent phases aim to upscale this technology with suitable industrial partners from South Africa and Germany. This strategic collaboration will allow South Africa's coal-dependent economy to responsibly step towards a stronger renewable energy future.

Source: Fraunhofer IGB

Kelvin Power Station's ground-breaking carbon capture pilot project

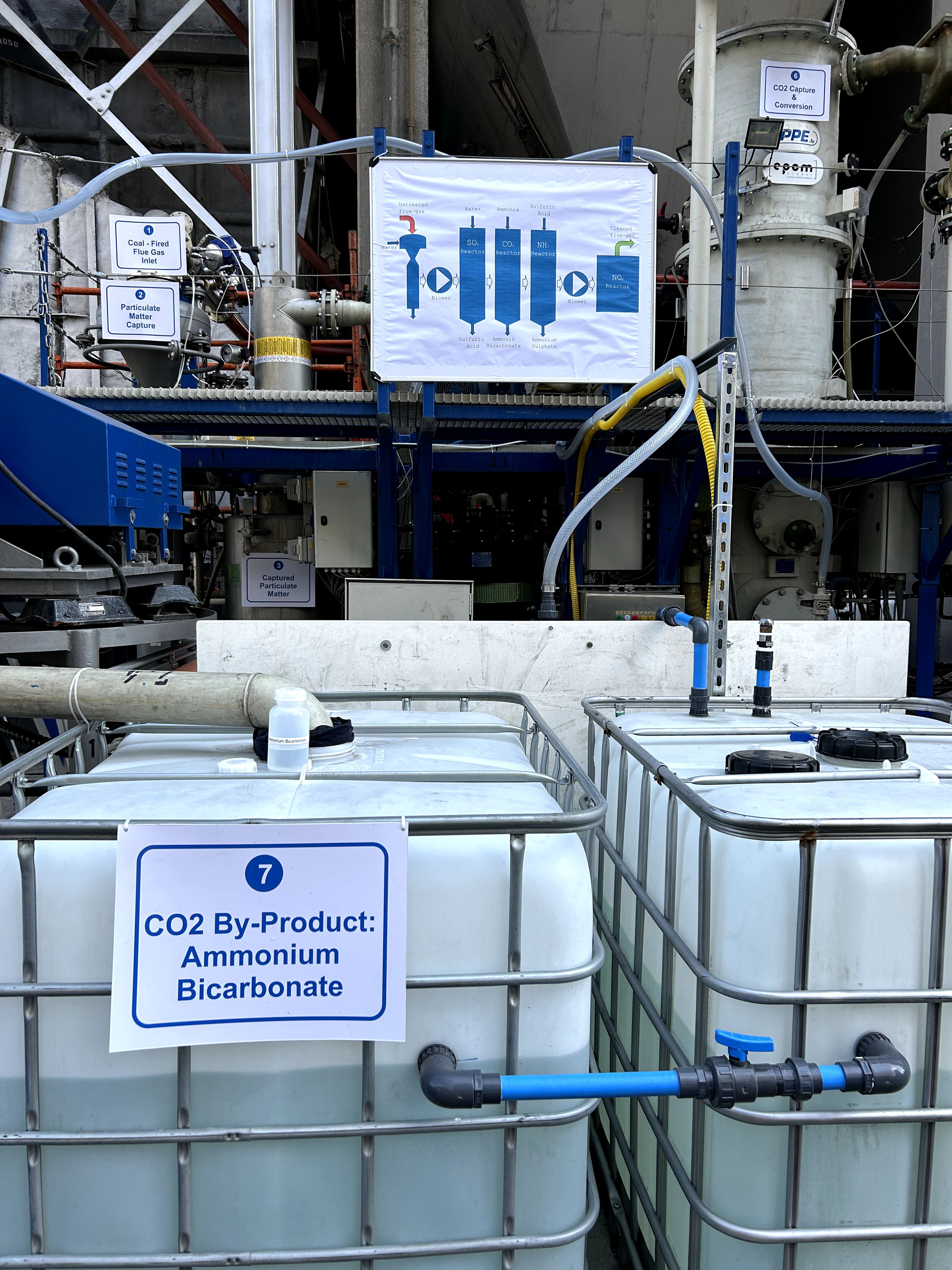

An exciting pilot project was conducted at the 600MW Kelvin coal power station in Isando, Ekurhuleni, where a 300m3/h flue gas capture unit was demostrated. This Multi-Pollutant Abatement System extracts carbon dioxide (CO₂), nitrogen oxides (NOₓ) and sulphur oxides (SOₓ) from the country’s emissions to produce:

- Sulfuric acid

- Ammonium sulphate

- Ammonium bicarbonate (ABC) crystals

The project was a collaboration between the Department of Science and Innovation (DSI) under the institution’s Hydrogen Society Roadmap, along with EPCM Global, Fraunhofer IGB a Luxembourg industrial gases cleaning company, Carbon Process & Plant Engineering (CPPE). The pilot project demonstrated the real-world viability of emissions-to-product conversion at scale.

Chemicals producer Omnia has already formulated a marketable fertiliser using the pilot plant's converted salts. With food security a national priority, such agricultural spin-offs could drive economic growth in rural communities.

EPCM Global CEO, Tumi Kgomo, talks about the impact of the project

According to EPCM Global CEO, Tumi Kgomo, the CoalCO2-X™ programme is the first of its kind in the world to comprehensively scrub almost all combustion gases and convert them into valuable industrial chemicals.

- Sulphur dioxide (SO₂) is converted into sulfuric acid, one of the world's most important industrial chemicals

- Carbon dioxide (CO₂) is captured using ammonia ato produce ammonium bicarbonate fertiliser

- Any residual ammonia left over in the plant is then combined with the captured sulphur to create ammonium sulphate fertiliser, ideal for maize production

"This plant will help solve food security for South Africa while meeting clean air compliance by scrubbing up to 90% of flue gas," states Kgomo.

For emissions-intensive industries, this first-of-its-kind solution presents an economically viable path to reduce their environmental footprint without having to invest in entirely new assets. "Heavy emitters can now invest in diversifying existing assets for value-added products instead of costly infrastructure replacements," Kgomo explains. Furthermore, consolidating and processing South Africa's industrial flue gas streams could create a chemical production output rivalling current coal export volumes.

Kgomo credits the Department of Science and Innovation's (DSI) long-term vision for getting the CoalCO2-X programme off the ground back in 2019. "DSI understood what we were trying to achieve with this technology. They developed a 10-year project arrangement to support developing and deploying it across relevant industries.”

EPCM Global’s mission: empowering industries, uplifting communities

As a management consulting firm, EPCM Global focuses on researching and developing innovative solutions that tackle major challenges facing the public and private sectors. Their core expertise lies in Multi-Pollutant Emissions Abatement Technology that facilitates the circular economy.

Under the CoalCO2-X programme with the Department of Science and Innovation (DSI), EPCM Global believes that South Africa has the potential to become a global hub for the rapidly expanding hydrogen and clean energy economy.

EPCM Global’s consulting services, project management and staffing solutions support this transition by reorganising resources and facilitating collaborative networks between industries, experts and government.

Access local circular economy technology through our innovation bridge

Reducing environmental impact while driving economic progress is a national imperative. Through programmes like CoalCO2-X and platforms like Innovation Bridge, the Department of Science and Innovation (DSI) promotes and facilitates collaboration around local technology innovations in zero-waste manufacturing and emissions conversion. The platform showcases solutions that:

- Convert plastic waste into energy

- Transform acid mine drainage into reusable water for irrigation in the agriculture sector

- Convert carbon dioxide (CO₂) emissions and other harmful gases into fertilisers

By connecting corporates, industries and experts, this hub accelerates the adoption of these circular economy innovations. South African businesses can explore the latest developments, engage with project leaders and form partnerships to implement sustainable solutions at innovation.bridge.info. DSI, making sure it’s possible.